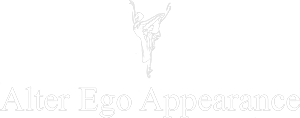

LIGHTNESS ENGINEERED

Reels

Where aerospace materials meet obsessive precision.

Where physics demands lightness. Where beauty refuses compromise.

Because these instruments deserve completion. Because collectors understand distinction between good enough and good. Because lightness matters. Because beauty rotates at 15 inches per second, and every revolution either validates vision or exposes compromise.

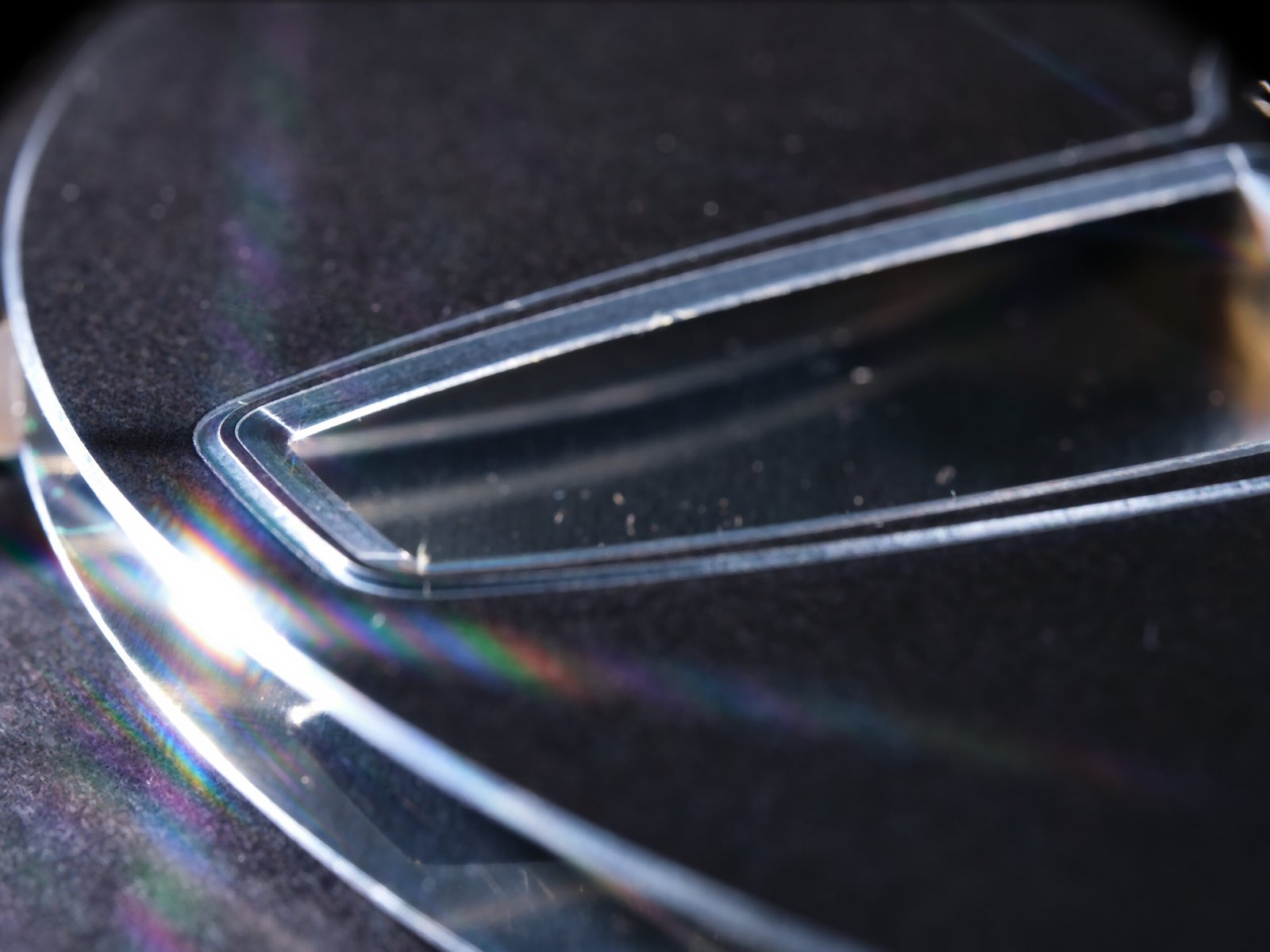

Completing the Instrument

Tape machines without extraordinary reels resemble grand pianos with plastic keys. Functional. Technically complete. Aesthetically bankrupt.

Our reels don’t merely rotate. They complete visual narratives. They extend design language from stationary panels to spinning elements. They transform utilitarian components into kinetic sculpture worthy of machines demanding months of obsessive creation.

Each set engineered specifically.

Each balanced to mathematical precision.

Each finished where adequacy becomes insult.

Weight matters. Materials matter. Precision matters. But ultimately, completion matters most. The machine receives reels worthy of months spent reimagining what vintage design becomes when freed from original constraints. Circle closes. Vision completes. Instrument achieves coherence from front panel to final spinning element.

The Truth About Reel Creation

We create singular sets for specific instruments. No catalog. No inventory. Occasionally, during creative surges, new designs emerge from workshop solitude — explorations that expand what we thought possible in rotating metal poetry.

Custom designs welcome. Fair warning: this takes time. Not because we’re slow. Because clients discover infinite possibilities once constraints disappear. The design phase — where imagination meets CAD software — can stretch weeks while minds change, evolve, reconsider. We understand. Perfection demands iteration. Just know this going in.

Before any reel spins for the first time, considerable sacrifice occurs: hours vanish into software, kilograms of aluminum become scrap, end mills snap pursuing impossible tolerances, fixtures emerge then become obsolete. This is the cost of singular work. We accept it. You fund it.

The Physics of Rotation

Mass fights momentum. Inertia resists change. Motors strain. Tape stretches.

Lightness solves problems before they emerge.

Our Material Palette

Every material selected for strength-to-weight ratio that makes engineers smile. No heavy metals. No compromises born from aesthetic desire overwhelming mechanical reality.

Base Structures

- Aluminum Alloys: 6061-T6, 7075-T6 — aerospace standards

- Magnesium: Extreme lightness, distinctive character

- Titanium Grade 5: Ti-6Al-4V — when weight meets immortality

- Carbon Fiber: Woven aerospace composites

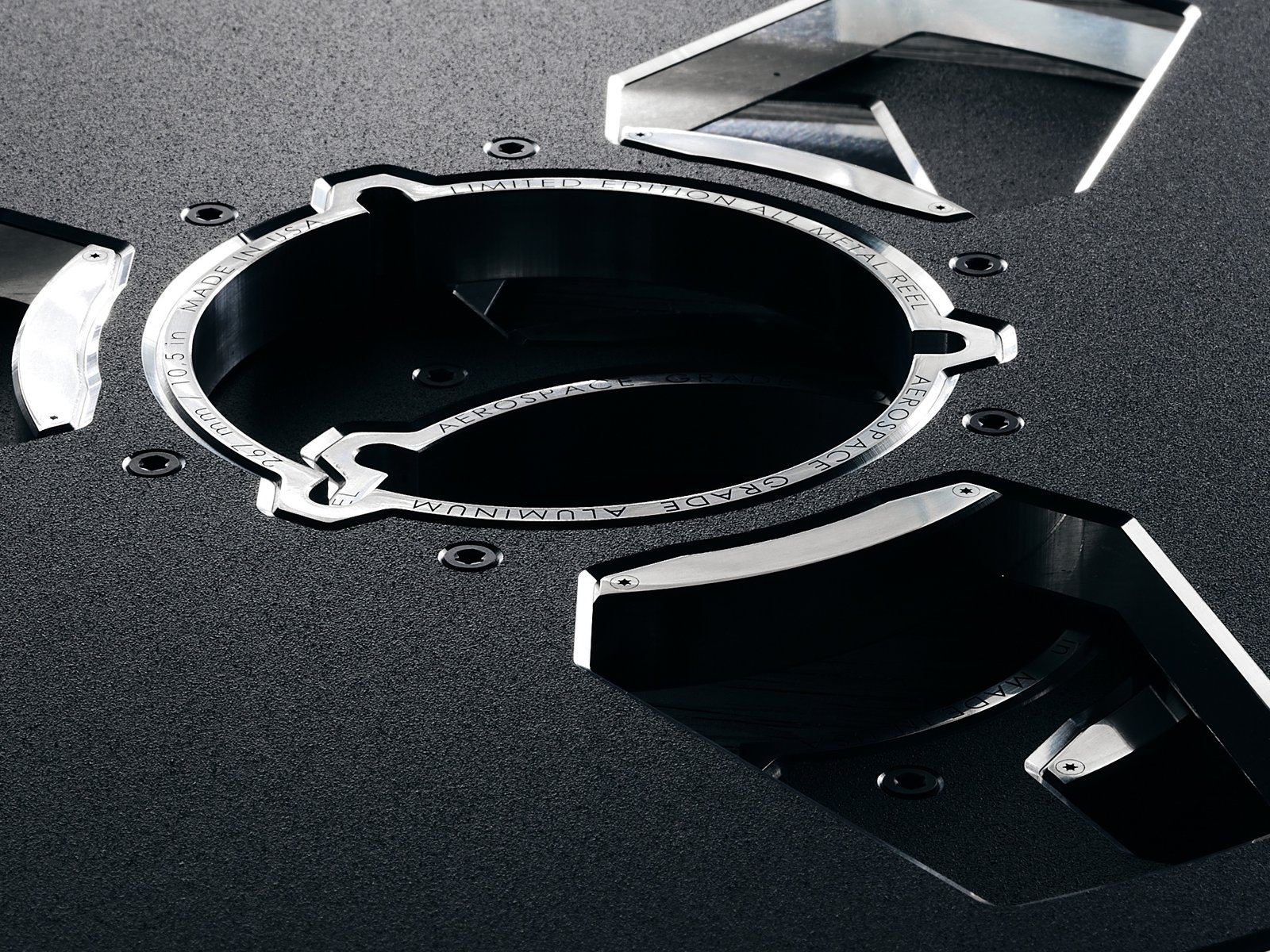

Surface Expressions

- Anodizing: Type II, Type III, spectrum of colors

- Powder Coating: Thermosetting perfection

- Polishing: Mirror, brushed, bead-blasted

- Metal Letterforms: Any metal. Including gold. Including platinum.

Engineering Intensity

01

CAD Obsession

Solidworks. Fusion360. Every curve mathematically perfect. Weight simulation through hundreds of iterations. Balance in mind. This is where 50-100 hours disappear per design.

02

Fixture Sacrifice

New vacuum fixtures CNC-machined for each design. Large 6061-T6 aluminum plate become single-use tool. These never survive design evolution. Permanent waste in pursuit of temporary perfection.

03

Material Sacrifice

Test cuts teaching what software cannot predict. Failed experiments measuring material behavior. Kilograms of premium metal joining scrap pile. End mills snapping. Drill bits dulling. Tools breaking in pursuit of tolerances that shouldn’t exist.

What Gets Consumed Creating One Design

CAD Engineering: 50-100 hours per design

Fixture Manufacturing: 12-36 hours design + 10-24 hours machining

Material Waste: $200-800 in aluminum/titanium/magnesium scrap

Broken Tools: End mills, drill bits, cutters consumed during development

Prototype Iterations: 3-7 versions before approval

Final Balancing: Precision to 0.02g per reel

This explains timeline. This explains investment. This is why we create singular sets, not catalogs.

Created Works

Each set tells its own story. Most remain with their instruments.

Occasionally, new creations seek their perfect match.

Custom Creation: The Reality

Where possibility meets patience. Where vision confronts timeline.

Where enthusiasm discovers the iterative nature of perfection.

Within Our Capabilities

Any design that physics permits and software can model. Conventional forms. Radical departures. Geometries not yet imagined.

Any material from our lightweight arsenal: aluminum alloys, magnesium, titanium, carbon fiber composites.

Any finish our processes enable: anodizing’s spectrum, powder coating’s durability, polishing’s reflections.

Metal letterforms in materials transcending base structure — gold, platinum, exotic alloys applied through proprietary integration.

Sizes: 7″, 10.5″, 14″ diameter. Custom dimensions considered when engineering justifies deviation.

Timeline & Terms

Creation Time: Up to 5 months

Not because we’re slow. Because custom design takes time. Considerable time.Clients discover infinite possibilities once constraints vanish. Minds change. Visions evolve. Revisions accumulate. We understand — perfection demands iteration. Just know this extends timeline.

Investment Range: $1,500-$15,000+ per set

Dependent on materials selected (titanium costs more than aluminum), size (14″ requires more material than 7″), complexity (simple elegance versus intricate detailing), and letterform integration (gold costs more than aluminum).

Payment Terms: 100% prepayment required

We don’t need someone else’s design occupying our storage while we chase payment. You commit fully. We commit fully. Simple economics.

Before You Contact Us

Time is finite. Yours. Ours. These steps ensure productive conversation rather than preliminary exploration.

1. Consider Your Design Vision

We need visual reference. Prepare examples showing what attracts you aesthetically. These can be:

- • Photos of reels you admire (any source)

- • Sketches or drawings (hand-made perfectly acceptable)

- • Images showing desired finishes, colors, textures

- • Your existing machine’s aesthetic for context

- • Reference images from unrelated fields (architecture, industrial design, nature)

We don’t need CAD files. We need understanding of what speaks to you visually.

2. Understand Investment Reality

Custom reel sets: $1,500 to $15,000+ per set

Variables affecting cost:

- • Material selection (aluminum least expensive, titanium most)

- • Size (7″ least material, 14″ most material)

- • Complexity (simple elegance versus intricate detailing)

- • Letterform integration (aluminum included, gold/platinum additional)

If this range causes hesitation, we’re not aligned. No judgment. Just reality.

3. Timeline Acceptance

Up to 5 months from commission to completion. This includes design iteration (where clients explore possibilities and refine vision), engineering, prototyping, fabrication, finishing. If you need reels next month, we cannot help. If you appreciate process requiring proper time, we align.

4. Commitment Understanding

100% prepayment required upon commission approval. After we discuss vision, agree on approach, establish specifications — payment precedes work. This protects both parties. You receive full commitment to your project. We don’t chase payment while your design occupies workshop space.

Coming prepared with visual references, budget acceptance, timeline understanding, and commitment readiness transforms conversation from exploration to execution. This benefits everyone.

Begin Conversation

Custom reel creation starts with dialogue, not transaction. We discuss vision, timeline expectations, material preferences, budget reality. Then, if alignment exists, work begins.

Serious inquiries only. Custom work demands significant time investment in consultation and engineering.