SELECTED WORKS

The Collection

Our workshop has produced considerably more instruments than those presented here. What follows represents a curated selection — the most iconic expressions of our craft, each pushing the boundaries of what’s possible in the marriage of vintage soul and modern precision.

These are not merely restorations. They are reimaginings, evolutions, singular creations that exist nowhere else.

Each instrument represents months of obsessive craftsmanship. No two are alike. Each is a distinct evolution in materials, technique, and vision.

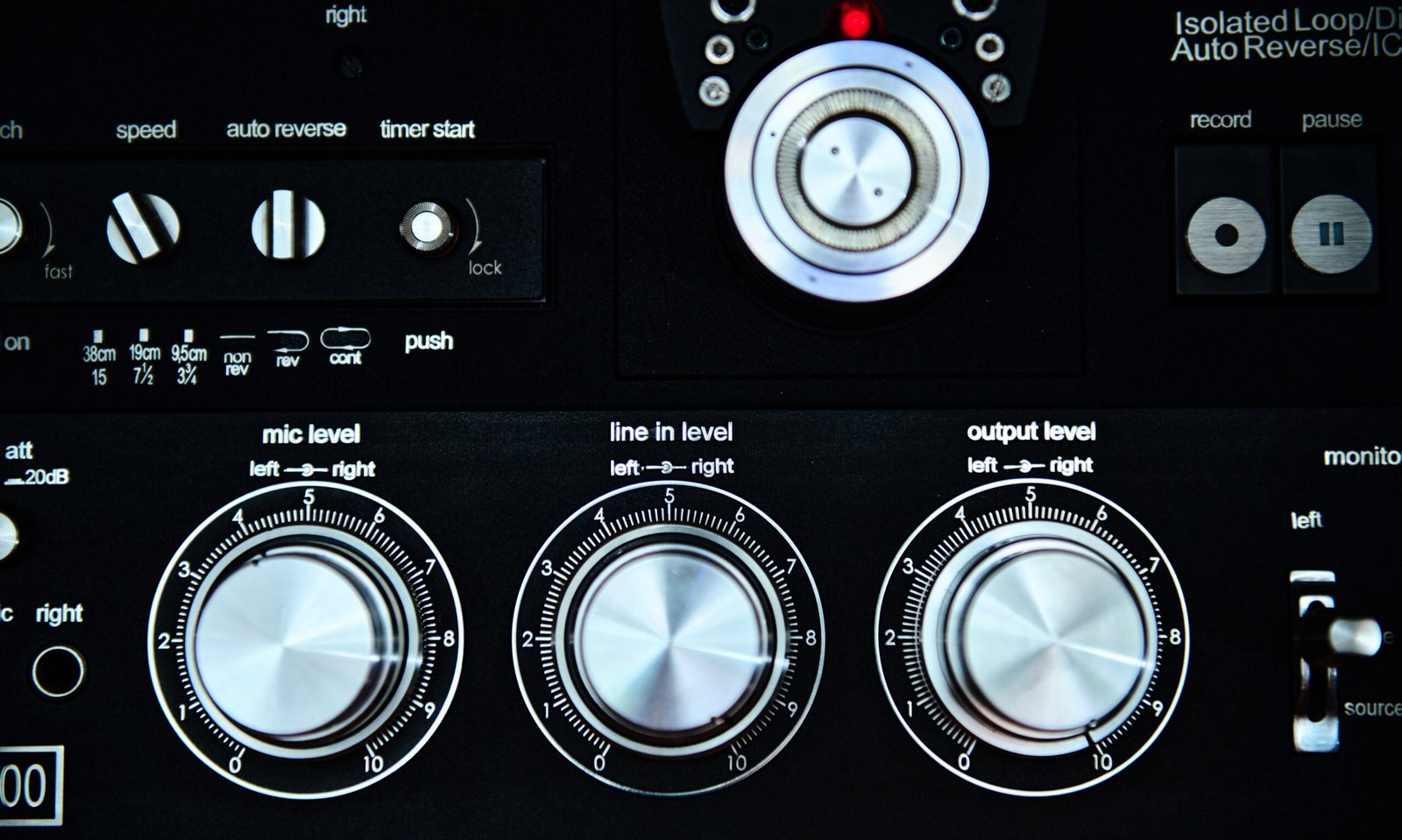

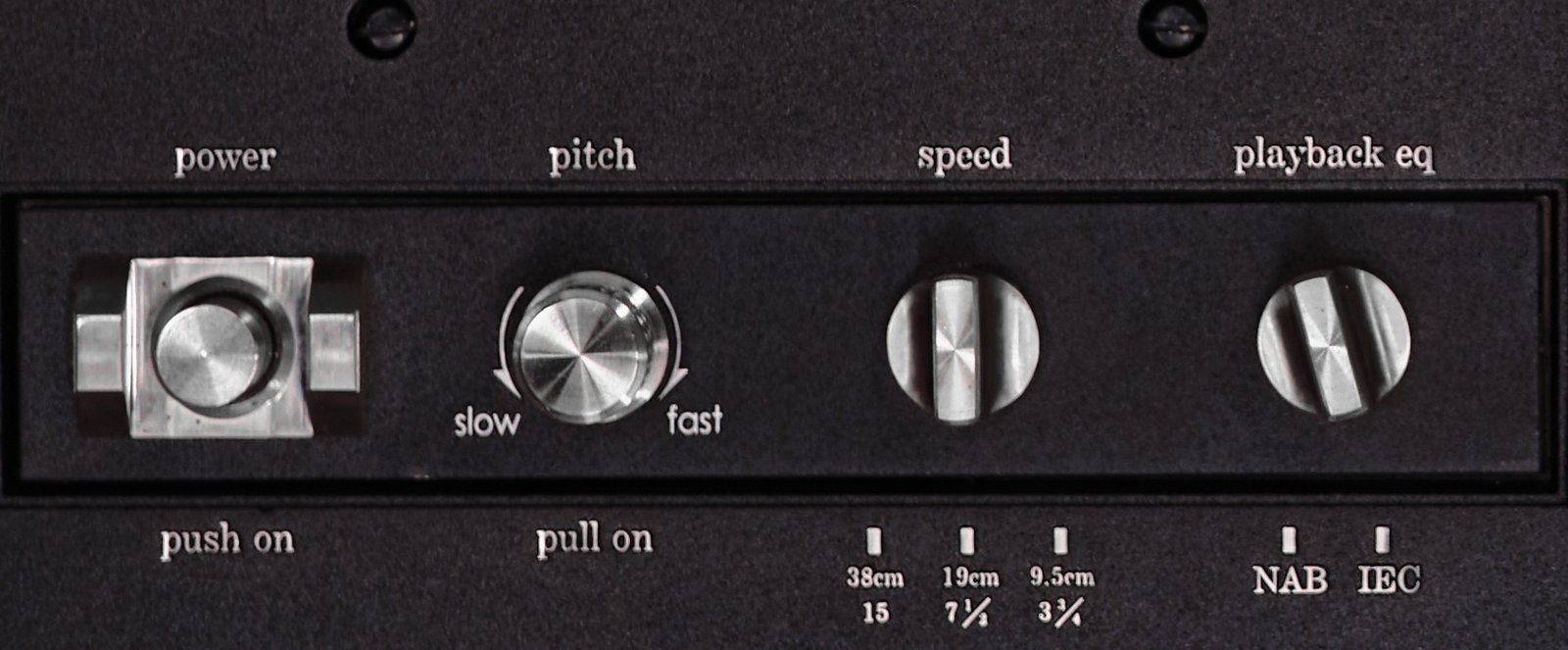

Technics RS-1500 Album Aereum

Technics RS-1500 — Album Aereum Edition

15 months of obsessive reimagining

The Philosophy

Total deconstruction precedes evolution. This RS-1500 ceased to exist as its original self before transformation could begin. Every fastener, every bearing, every component reduced to individual elements — a complete diaspora of vintage engineering, awaiting renaissance through contemporary vision.

Foundational Principles

The rebuild begins at the atomic level. Original Phillips-head fasteners — prone to corrosion, weakness, temporal decay — replaced entirely with precision hex-head stainless steel. These will outlive their creators. Certain components refused renewal; for these, we created replacements on CNC machines, manufacturing single-quantity parts that exist nowhere in any catalog.

The Canvas: Panel Preparation

Front panels stripped to bare aluminum, their decades of service erased. Hand-sanding removes every imperfection — each scratch a memory deleted, each dent a history corrected. The metal emerges virginal, ready for transformation. Only when surface perfection achieves flawlessness do we proceed.

Metal as Language: The Lettering

White bronze letterforms — not printed, not adhered, but integrated. Our proprietary process remains ours alone. Each character placed with architectural precision, becoming one with the panel before powder coating encases all. Caveman Black from Prismatic Powders provides the void against which bronze will sing. Post-cure, we return to each letter, polishing to mirror luminescence. The result: three-dimensional typography that catches light like water, readable by touch as much as sight.

The Soul: Electronics Reimagined

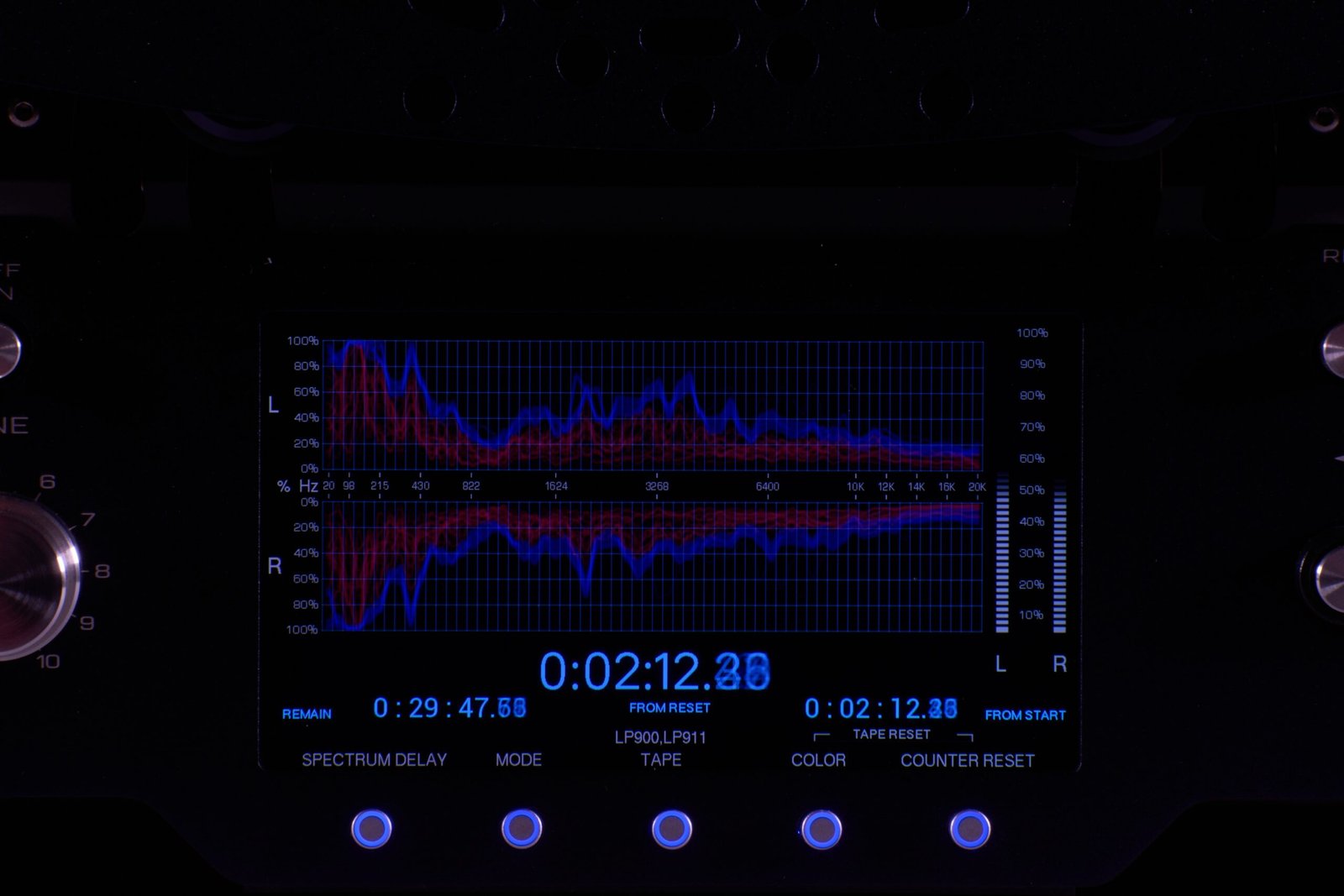

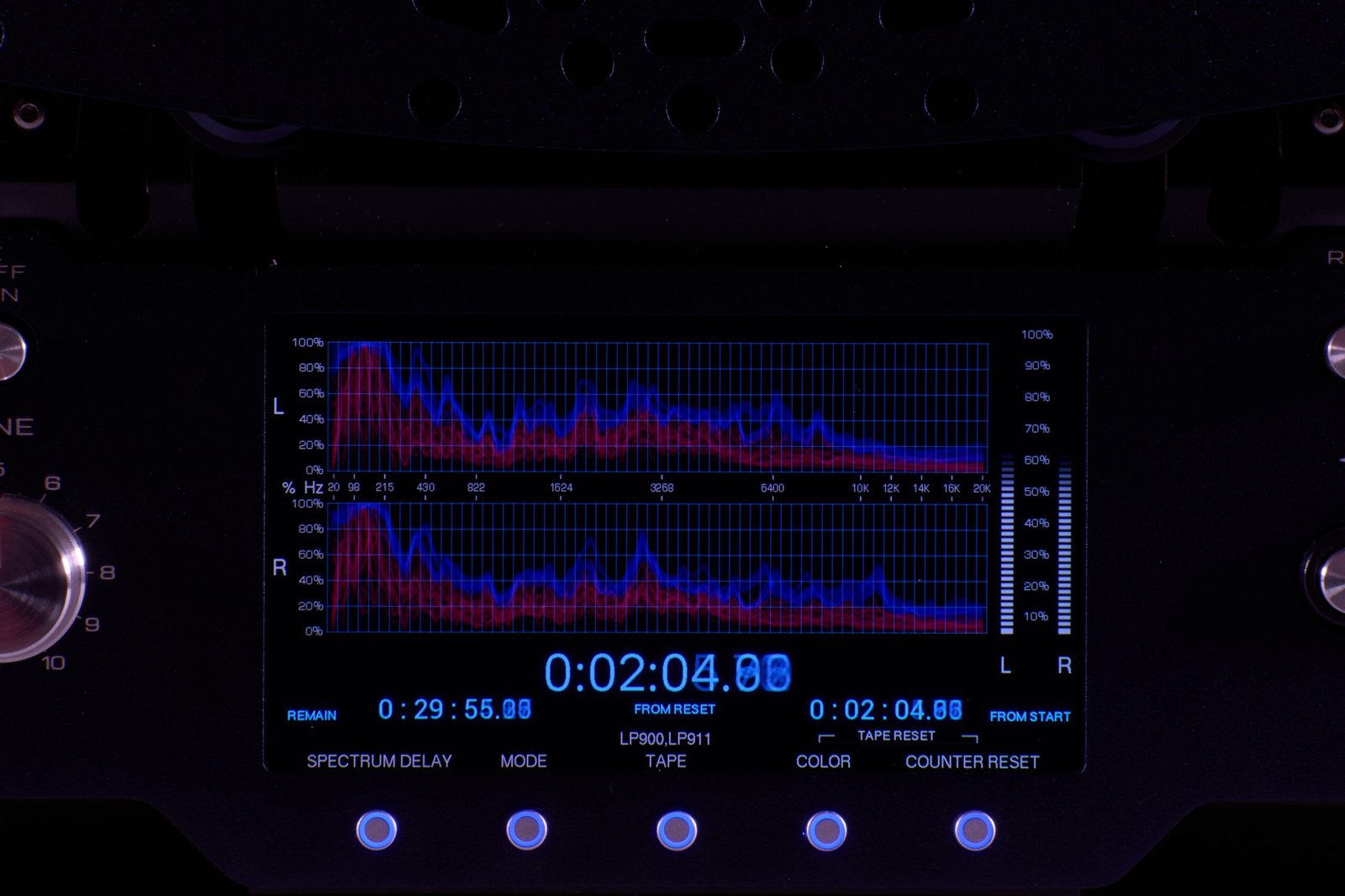

Every capacitor extracted and replaced with audiophile-grade components. Signal path purified. Where vintage VU meters once flickered, now custom LCD screens glow with eight distinct personalities — backgrounds programmed to shift mood and aesthetic. Two pay homage to D’Agostino’s austere elegance, designed to harmonize with systems of that pedigree. Your preference dictates the display; reprogramming remains available upon request.

The mechanical tape counter — imprecise, approximate — replaced with electronic precision measuring to one-hundredth of a second. Time itself held accountable.

Playback equalization switching added: NAB or IEC selectable, ensuring compatibility across tape standards and geographical preferences. Precision without compromise.

Rear panel connectors replaced entirely with audiophile-grade gold-plated terminals — signal integrity preserved from tape head to amplifier. The power cord itself renewed, because even AC delivery affects sonic character. No detail deemed too minor for reconsideration.

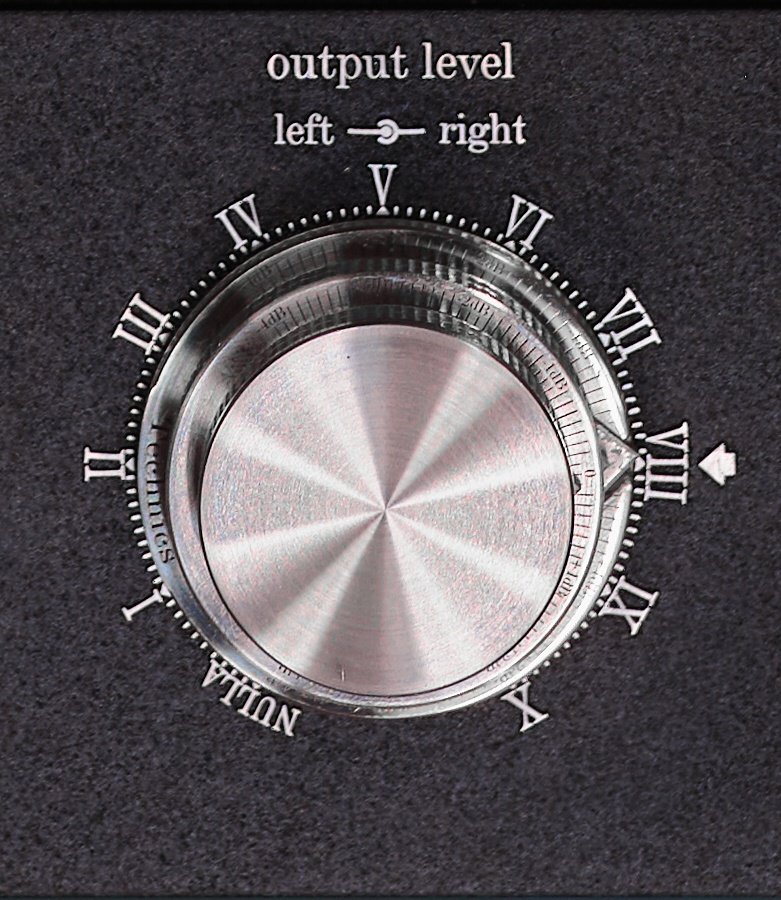

Tactile Symphony: Controls Reborn

Every knob, every lever: white bronze. Not sourced. Not salvaged. Created.

We melt virgin white bronze alloy, pour it into graphite molds CNC-machined specifically for this instrument’s geometry. These castings become stock material for further CNC refinement, each control surface shaped by computer-guided carbide. Post-machining processes ensure surfaces that beg to be touched — functional sculpture, engineering as jewelry.

Living Wood: The Panels

White oak — not merely finished, but transformed. Stabilized through Cactus Juice polymer infusion under vacuum and pressure, these panels will survive centuries unchanged. Darkened through controlled processes, baked to permanence, then polished to silk. The result feels impossibly smooth, appears impossibly deep. Protective metal flanges guard top and bottom edges — function meeting form, defense as design element.

Invisible Excellence

Magnetic heads: replaced with new-old-stock perfection. Even the motors — the mechanical hearts few would question — disassembled completely. Bearings replaced. Lubricants renewed. Every rotating element balanced, every friction point optimized. The machine whispers where it once hummed.

The Result

What emerges transcends its origins. The RS-1500 was legendary. This instrument is singular. Album Aereum — “white bronze” in Latin, a metal prized since antiquity for its luminous quality — captures the philosophy: ancient materials, timeless techniques, contemporary precision.

No other machine exists with this exact combination of materials, processes, and vision. This is not replication. This is evolution through obsession.

Status: Available

Completion: 2024

Time Investment: 15 months

Documentation: Workshop photography available upon request

For acquisition inquiries or to commission your own instrument, contact us directly or through our authorized dealer network.

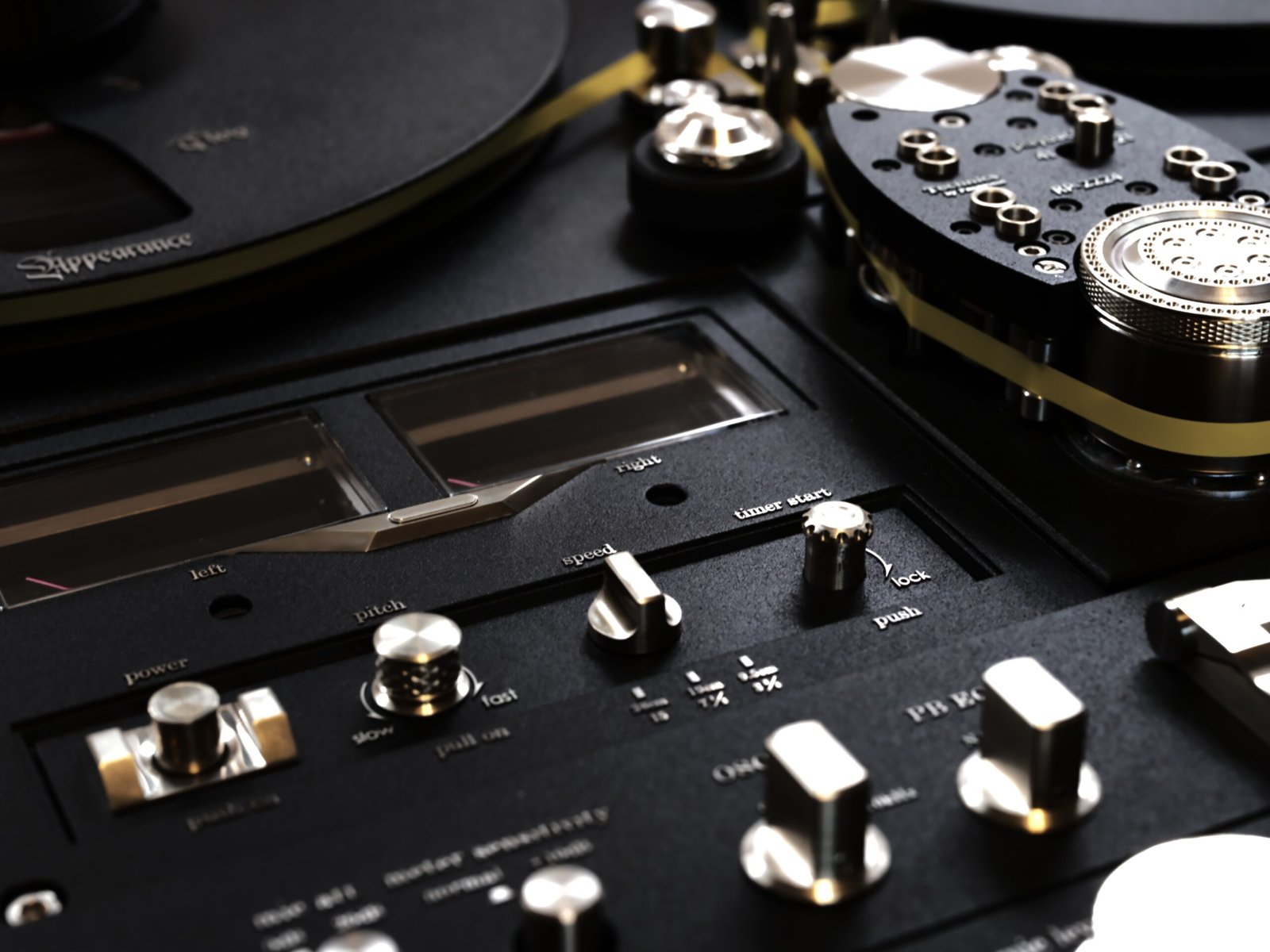

Technics RS-1520 Album Aereum

Technics RS-1520 — Album Aereum Edition

15 months of obsessive reimagining

The Grail

Audiophiles speak of the RS-1520 in hushed tones — Technics’ two-track pinnacle, transformer-coupled perfection, the machine other machines aspire to become. Rare in original form, rarer still in pristine condition, impossible in this incarnation. What you witness here exists as singular artifact. Another RS-1520 bearing the Album Aereum treatment will not emerge from our workshop soon, if ever. We do not mass-produce dreams.

Destruction as Genesis

To remake perfection, first unmake it completely. This RS-1520 surrendered its identity bolt by bolt, bearing by bearing, until only constituent elements remained scattered across our bench — a constellation of vintage engineering awaiting resurrection through modern obsession. Created alongside its RS-1500 sibling, these twins share aesthetic DNA while serving different sonic destinies. The 1520’s two-track purity demands even greater precision, rewards even smaller refinements.

Foundation: The Invisible Architecture

Phillips-head screws — corrode-prone relics of expedient manufacturing — expelled entirely. Their replacements: hex-head stainless steel engineered to outlast continents. Components deemed unworthy of renewal we replaced with parts that exist in no catalog, manufactured on CNC equipment in single quantity. This machine contains pieces that will never be reproduced, born once for this singular purpose.

Surface as Statement: Panel Metamorphosis

Aluminum panels stripped to nakedness, decades of fingerprints and micro-abrasions erased through methodical hand-sanding. What emerges: virgin metal, perfect as the day it left the mill, ready to accept its destiny. We work the surface until light itself reflects without distortion, until imperfection becomes theoretical rather than actual.

White Bronze: The Luminous Alphabet

Our proprietary lettering process — developed over years, perfected through countless failures, known only to us — integrates white bronze characters into aluminum substrate. Not adhesive. Not mechanical fastening. Integration. The bronze becomes inseparable from panel, sharing molecular bonds.

Caveman Black powder coating follows, encasing everything in obsidian depths. Then: revelation. We return to each letter with abrasives and compounds, polishing bronze to mirror finish while leaving surrounding black untouched. The effect: luminous typography suspended in darkness, letters that shift with viewing angle, catching ambient light like captured stars. Run your fingers across the surface — you feel dimension, topography, metal speaking in three dimensions.

This appearance exists nowhere else. Cannot be purchased. Cannot be replicated without our processes, our equipment, our accumulated knowledge of how bronze bonds to aluminum, how powder coating flows around metal, how polishing reveals without disturbing.

The Splicer: Function as Jewelry

Integrated into the front panel — where it belongs, where hands can reach it instinctively — a tape splicer crafted entirely from white bronze. Not bolted on as afterthought. Not purchased from catalogs. Created.

We cast this splicer using the same graphite molds and virgin white bronze alloy that birth the control surfaces. CNC refinement follows, shaping the cutting guide, the blade channel, the tape positioning rails to tolerances that transform utility into ceremony.

This is surgery made visible. The act of splicing tape elevated from mechanical necessity to ritual. Every edit, every join, every splice becomes interaction with an instrument within the instrument. The splicer shares the panel’s visual language — white bronze against black void — creating aesthetic continuity while serving immediate, tactile purpose.

No other RS-1520 offers this. To splice tape on lesser machines requires removing it, carrying it elsewhere, using separate tools. Here, precision lives at your fingertips, integrated as naturally as the transport controls, as essential as the heads themselves. Form bowing to function, function elevated to art.

Electronics: Honoring Legacy Through Transcendence

The RS-1520’s transformer-coupled topology made it legendary among those who listen critically. We preserve this sonic signature while purging every capacitor, replacing each with audiophile-grade components sourced for specifications that exceed original parts by orders of magnitude. The warmth remains. The noise floor vanishes.

Where mechanical VU meters once danced, now LCD screens pulse with eight programmable personalities. Two backgrounds reference D’Agostino’s minimalist philosophy — for systems of that caliber, visual harmony matters. The display answers to your preference; reprogramming costs nothing but an email.

Mechanical tape counters lie. This one tells truth: electronic precision to one-hundredth second, because tape position matters when every second contains art.

Gold-plated audiophile connectors replace aging rear panel terminals. The power cord itself renewed, carrying clean AC to circuits that now demand it. In machines this revealing, every connection point affects what you hear.

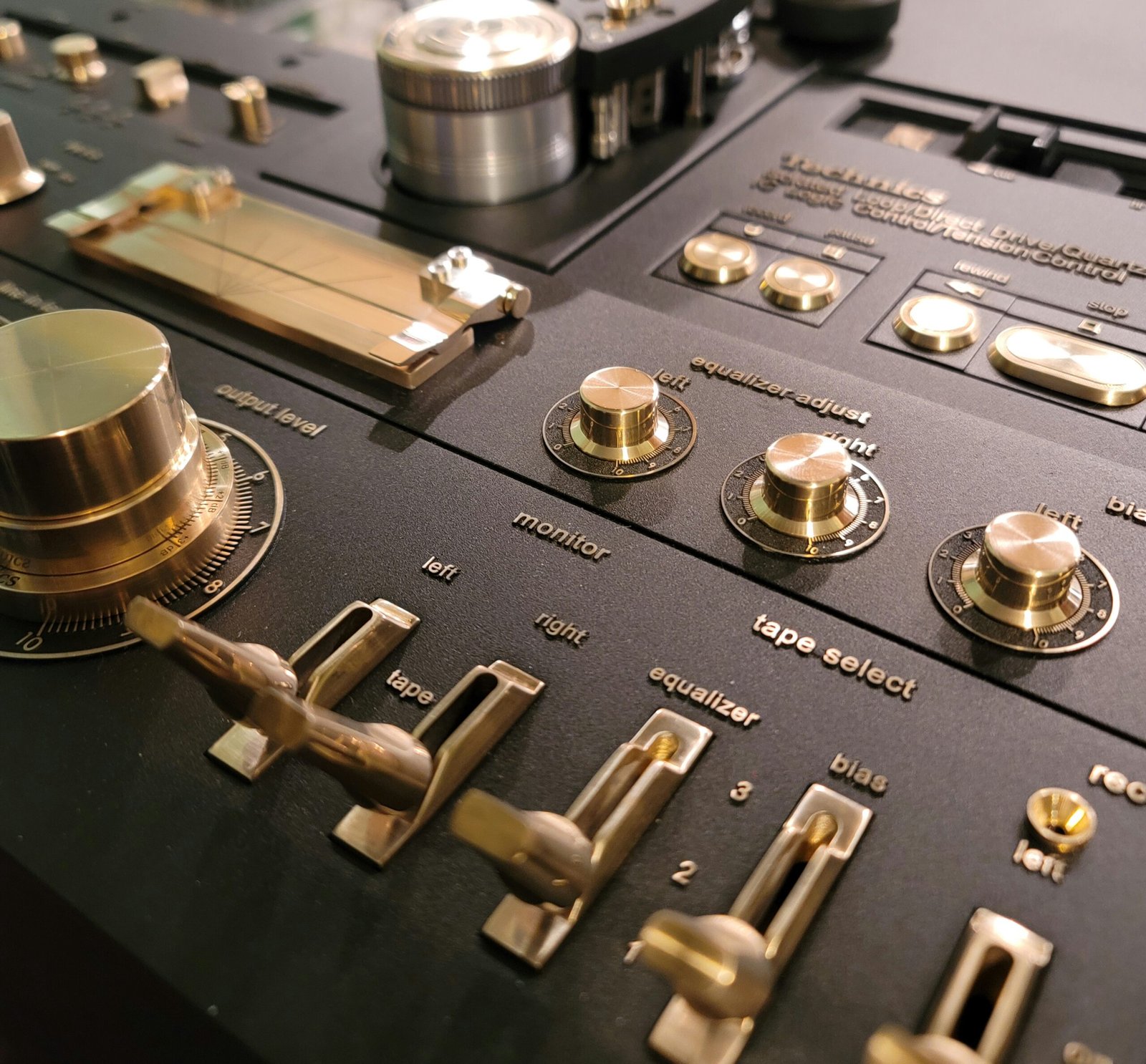

Tactile Poetry: Controls as Sculpture

White bronze knobs and levers, each a small monument to precision manufacturing. We melt virgin alloy, pour it into graphite forms machined specifically for this instrument’s geometry. These molds will never touch another machine — they exist for this RS-1520 alone.

Cast bronze becomes raw material for CNC refinement. Computer-guided carbide shapes each control surface to tolerances measured in microns. Post-processing follows: deburring, polishing, surface treatments that transform functional components into objects that demand interaction. These are not knobs. These are invitations to touch, to feel mass and friction, to experience mechanics as sensory pleasure.

Wood as Time Compressed

White oak selected for grain, for density, for how it accepts transformation. Stabilization through Cactus Juice — polymer infusion under vacuum — renders these panels impervious to humidity, temperature, time itself. They will outlive great-grandchildren of the original owner.

Darkening processes follow, controlled chemistry creating depth that appears infinite. Baking sets the color permanently. Final polishing achieves silk — impossibly smooth, disturbingly pleasant against skin. Protective metal flanges guard edges where hands might meet wood, function disguised as design choice.

The Invisible Obsession

New magnetic heads — two-track configuration demands perfection here. Alignment tolerances that would satisfy most manufacturers we consider starting points. Even motor assemblies, which most would leave undisturbed, we dismantle completely. Bearings replaced. Lubricants renewed. Balance checked, friction optimized. The RS-1520 was legendarily smooth. This one whispers secrets.

Singularity

No other RS-1520 wears this skin, contains these materials, embodies this specific intersection of technique and vision. Another Album Aereum 1520 would require another 15 months, assuming we chose to recreate rather than evolve. We prefer evolution. The next 1520 to leave our workshop — if another 1520 enters at all — will explore different territory, different materials, different expressions of what this legendary machine can become.

This one stands alone. Unrepeatable. Already history.

Status: Sold

Completion: 2024

Time Investment: 15 months

Current Location: Private collection

Documentation: Workshop photography available upon request

Note: The next RS-1520 transformation is not anticipated in the near future

For those seeking similar transformations or to commission your own instrument, contact us directly or through our authorized dealer network. Each creation is unique; timelines begin at 12 months.

Technics RS-1520 Bronze Age

Technics RS-1520 — Bronze Age Edition

12 months of intimate collaboration with time itself

Captured Before Release

This instrument never experienced the indignity of waiting. Offered for acquisition, claimed immediately, vanished into private collection before most knew of its existence. Such is the fate of work that speaks directly to those who understand: bronze ages, wood breathes, time becomes collaborator. This RS-1520 will grow old alongside its owner, patina developing as shared biography, surface evolving as relationship deepens.

We will not make another soon.

Bronze as Philosophy

Where Album Aereum chose white bronze for luminous contrast, Bronze Age commits utterly to aluminum bronze — ancient alloy, weapon of empires, material that refuses static existence. Every visible metal surface speaks bronze: letterforms, control knobs, levers, even the fasteners securing front panels. This is not decoration. This is declaration.

Bronze lives. Oxidizes. Develops patina that reflects handling, environment, the oils of human skin, decades of atmosphere. The RS-1520 will not look in ten years as it looks today. It will look better — earned, weathered, possessed of history written in molecular changes across its surface. Owner and instrument age together, bronze documenting the journey.

Genesis Through Annihilation

Disassembly to atomic constituents. The RS-1520 ceased being RS-1520, became instead raw potential scattered across workbench — bearings separated from shafts, capacitors extracted from boards, panels divorced from chassis. Only through complete destruction could complete reimagining occur.

Foundation Reimagined

Phillips-head screws — corrode-prone, time-limited, unworthy — expelled entirely. Their successors: stainless steel hex-head fasteners that will outlive civilizations. Components requiring renewal received parts manufactured specifically for this singular instrument. Nothing salvaged from catalogs. Everything considered, nothing accepted without interrogation.

Surface as Sacrament

Front panels stripped to bare aluminum through methodical hand-sanding, decades of service marks erased until virgin metal emerged — flawless, ready, waiting for bronze to arrive. We work surfaces to optical flatness, where reflection reveals no distortion, where imperfection becomes philosophical concept rather than physical reality.

Bronze Inlay: The Ancient Alphabet

Aluminum bronze letterforms integrated through proprietary process developed over years, perfected through failure, protected as closely as family secrets. These characters do not adhere — they become panel, sharing molecular bonds, inseparable as matter itself.

Powder coating follows, encasing bronze and aluminum together. Then revelation: we return to each letter with abrasives and compounds, polishing bronze to mirror luminescence while leaving surrounding powder coat untouched. But unlike white bronze’s eternal shine, aluminum bronze begins its transformation immediately. Oxygen finds it. Time claims it. Patina whispers across surfaces, darkening here, greening there, creating topography of use and exposure.

This is intentional. This is beautiful. This is bronze accepting its destiny.

Front panel fasteners — visible, functional, honest — cast from the same aluminum bronze, each a small monument to material commitment. Where others hide screws, we celebrate them. Bronze speaks at every scale.

The Splicer: Horological Precision

Machined from solid aluminum bronze billet — not cast, not assembled, but revealed through CNC subtraction. What emerges from that bronze block resembles complications found in six-figure timepieces: spring-loaded levers that grip tape with calibrated tension, mechanisms that move with damped precision, surfaces finished to tolerances watchmakers would recognize.

The blade? Absent. This splicer holds tape for joining, not cutting — the philosophy being that tape deserves ceremony, not violence. Press the lever: spring-loaded mechanisms engage with satisfying mechanical authority, yet the spring itself remains invisible, hidden within bronze architecture. The action feels inevitable, perfectly weighted, exactly as urgent as it should be and no more.

Integrated into the front panel where hands find it instinctively, the splicer shares bronze’s commitment to aging gracefully. It will darken where fingers touch, polish where friction occurs, develop personality that reflects use. This is not accessory. This is extension of the instrument’s philosophy — time as collaborator, function as jewelry, mechanics as meditation.

No other RS-1520 offers this. To splice tape elsewhere requires removing it, taking it to other tools, breaking workflow. Here, precision lives at fingertips, bronze against bronze, watchmaker logic applied to tape handling.

VU Meters as Reliquaries

Custom backgrounds machined from thick copper sheet — not thin foil, not printed circuit board, but substantial metal with mass and presence. Deep laser engraving burns graphics into copper’s surface, creating relief topography. Powder coating follows, filling valleys, covering peaks.

Then: selective polishing. We remove powder coat from engraved graphics, revealing copper beneath, polishing it to mirror finish. The exposed copper then receives 24-karat gold plating — not for ostentation, but for permanence. Gold doesn’t tarnish. These meter faces will glow with precious metal warmth for centuries, contrasting with bronze’s inevitable patina, creating dialogue between metals: one changing, one eternal.

This is jewelry masquerading as electronics. This is craft serving function serving beauty.

OLED Counter: Time as Light

Where mechanical tape counters once clicked imprecisely forward, now OLED technology glows with gold-colored digits measuring to one-hundredth second. Not LED. Not LCD. OLED — organic light-emitting diodes creating luminescence from within, each digit a constellation of individual emitters.

Gold digits against black void echo the bronze-against-darkness aesthetic throughout. The precision: 1/100 second, because tape position matters when every moment contains music, when editing requires certainty measured in fractions. Time itself held accountable, displayed in light that appears to float rather than project, ethereal yet absolute.

This counter will measure decades of use, digits glowing identically in year twenty as in year one. Electronic permanence meeting bronze impermanence, digital certainty alongside analog evolution.

Palisander: The Exotic Skin

Palisander rosewood — dense, oily, so naturally stable that stabilization through polymer infusion becomes insult rather than improvement. This wood needs nothing from us except recognition and polishing.

We select panels for grain drama, for color depth, for the way light reveals complexity within darkness. Polishing follows — not to silk softness like oak, but to mirror. Hour after hour of progressively finer abrasives until the wood surface reflects like glass, until you see your face in rosewood, until the boundary between solid and reflection blurs.

Palisander’s natural oils create finish from within. No topcoat. No sealant. The wood itself becomes glassy through mechanical work alone, achieving impossible smoothness while retaining warmth that no synthetic finish can match.

Electronics: Invisible Excellence

Transformer-coupled topology preserved — the sonic signature that made the RS-1520 legendary among those who listen with intention. Every capacitor replaced with audiophile components exceeding original specifications by magnitudes. The warmth remains. The noise vanishes.

LCD screens with eight programmable backgrounds replace mechanical VU meters, though their copper-and-gold faces remain visible behind the displays — layers of time, old and new coexisting.

Gold-plated audiophile connectors replace aging rear terminals. Power cord renewed. Every electron’s path optimized, because bronze deserves electrons that flow cleanly.

Controls: Bronze as Tactile Language

Every knob, every lever: aluminum bronze cast in graphite molds machined uniquely for this instrument. These forms will never shape another machine. Cast bronze becomes raw material for CNC refinement — computer-guided carbide achieving tolerances measured in microns.

No protective coating. No sealer. Just bronze exposed to air, to touch, to time. These controls will darken with handling, polish with use, develop character that reflects interaction. Fingerprints become patina. Use becomes visible. The machine documents its own story.

The Invisible Obsession

Magnetic heads replaced with new-old-stock perfection. Motor assemblies completely disassembled — bearings renewed, lubricants replaced, balance optimized. The legendary RS-1520 smoothness refined to silence, friction reduced to theoretical minimum.

Every bolt. Every bearing. Every capacitor. Nothing assumed acceptable. Everything interrogated, everything renewed or replaced. The bronze you see represents philosophy extending throughout: if surface matters, interior matters more.

Living Metal, Living Wood

Bronze Age captures truth: these materials exist in time, change with time, partner with time. The machine will not look the same in a decade. Bronze will darken, develop verdigris, show where hands touch most frequently. Palisander will deepen, oils migrating through grain, creating richness that only decades can achieve.

This is not degradation. This is maturation.

The owner becomes curator, witness, collaborator. The machine ages alongside them, documents their journey together through molecular changes across bronze surfaces. This is intimacy impossible with static materials, relationship unavailable to machines that refuse to change.

Only the OLED counter remains unchanged — gold digits glowing identically across decades, digital permanence witnessing analog evolution.

Singularity and Immediacy

Offered for acquisition, claimed before announcement reached wider audience. Collectors who understand bronze’s language recognized immediately what this represented: RS-1520 perfection meeting materials that breathe, that live, that age with grace rather than fighting time.

Another Bronze Age RS-1520 would require another 12 months minimum, assuming we chose repetition over evolution. We choose evolution. The next RS-1520 — if another enters our workshop — will explore different territory entirely. Different materials. Different expression of what this legendary machine can become when obsession meets capability.

This one exists in private collection now, aging gracefully, developing character, becoming more itself with each passing day.

Status: Sold (Immediately upon offering)

Completion: 2023

Time Investment: 12 months

Current Location: Private collection, developing patina

Documentation: Workshop photography available upon request

Note: Bronze Age will not be repeated. Each RS-1520 we approach becomes unique expression.

For those seeking similar transformations or to commission your own instrument, understand: we create evolution, not repetition. Each machine explores new territory. Contact us directly or through our authorized dealer network. Timelines begin at 12 months. Some commissions claim themselves before public offering.

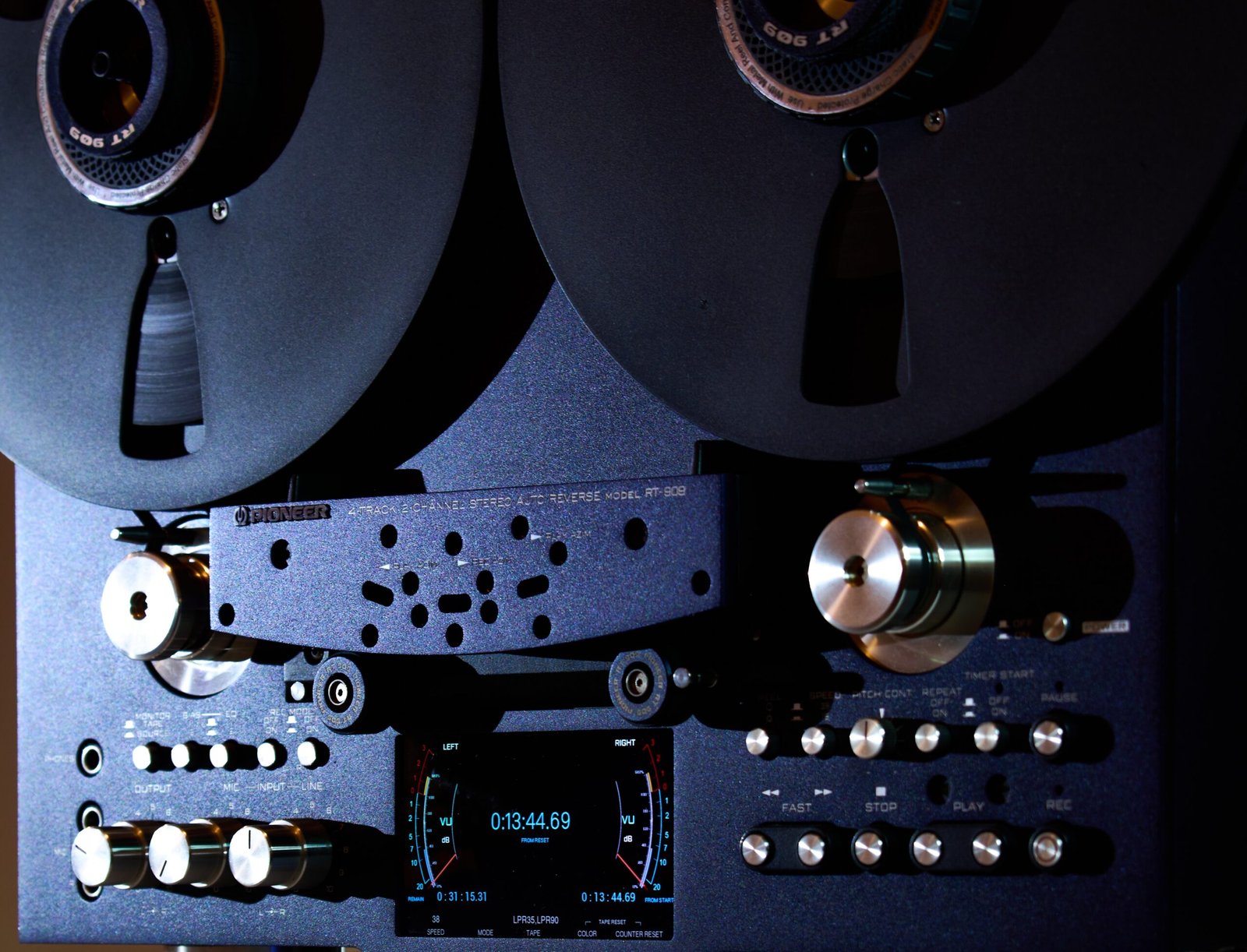

PIONEER RT909 Black Stone

Pioneer RT-909 — Black Stone Edition

9 months of technological resurrection

Timeless Modernity

The RT-909 approaches its fortieth year, yet refuses to age visually. Pioneer’s designers achieved something rare in 1985: aesthetic prescience. Clean lines, geometric certainty, proportions that transcend temporal fashion. This machine looks as contemporary today as the year it emerged — angular elegance that predicted minimalism decades before minimalism became doctrine.

We recognized this. Black Stone honors that timeless design while dragging the electronics screaming into the present century.

Obsidian Philosophy

Black Stone: volcanic glass, fracture-sharp edges, surfaces so dark they absorb light rather than reflect it. This edition embraces darkness completely. Caveman Black powder coating creates void-like depth, panels becoming portals rather than surfaces. Against this obsidian backdrop, silver letterforms float like constellations — not white bronze, not aluminum bronze, but pure silver-toned metal creating stark contrast.

This is monolith aesthetic. This is technology as sculpture. This is the RT-909 stripped to essential geometries, rendered in materials that refuse compromise.

Deconstruction as Prerequisite

Complete disassembly to constituent atoms. Bolts separated from panels, bearings extracted from shafts, circuit boards divorced from chassis. The RT-909 ceased existing as functional machine, became instead archaeological site awaiting excavation and reinterpretation.

Every component interrogated. Broken parts identified, discarded, replaced. Wear patterns studied. Friction points noted. Nothing assumed functional until proven. Nothing considered permanent until tested.

This is how machines should be rebuilt: with skepticism, with rigor, with refusal to accept “good enough.”

Foundation Renewed

All fasteners replaced — Phillips-head relics expelled in favor of stainless hex-head permanence. Every capacitor extracted and replaced with audiophile-grade components. Every belt renewed. Every bearing replaced. Lubrication points addressed methodically, friction reduced to theoretical minimums.

But these are preliminaries. Expected. The transformation begins where others stop.

Pinch Rollers: Surgical Reinvention

The original pinch rollers — adequate for their era, inadequate for ours — discarded entirely. In their place: completely new design machined from 316L stainless steel. Not chosen for appearance. Chosen for properties: non-magnetic (critical near tape heads), corrosion-proof, capable of mirror polish that endures decades.

Inside each roller: miniature precision bearings. Not salvaged. Not repurposed. Specified new, selected for tolerances measured in microns. The result: pinch action that contacts tape with calibrated pressure, rotation so smooth it approaches frictionless, surface so perfectly circular that wow and flutter measurements approach measurement equipment limitations.

These rollers will outlast their great-grandchildren. They represent what obsession achieves when function matters more than expedience.

Electronic Revolution: From Prehistoric to Present

The RT-909’s original electronics — primitive by contemporary standards, clunky implementations of tape counter and VU meter driving — removed entirely. Circuit boards containing 1980s logic: garbage. Not salvaged for nostalgia. Not repurposed. Discarded.

In their place: modern computing power. Custom PCBs housing 600MHz clock controller — processing speed that would have seemed science fiction when Pioneer designed the original. Audio ADC (analog-to-digital converter) sampling VU signals with resolution the original engineers never imagined. High-resolution screen driver pushing pixels at refresh rates that eliminate flicker, that create illusion of analog smoothness through digital precision.

High-precision encoders replace mechanical tape counter mechanisms. Not approximate. Not “close enough.” Precise to 1/100 second, because editing requires certainty, because tape position matters when every frame contains intention.

The Screen: Five Inches of Possibility

Original front panels removed. New panels CNC-machined to accommodate five-inch high-resolution display — singular screen replacing the RT-909’s twin primitive displays. What those two screens accomplished crudely, this one achieves with elegance.

VU meters and tape counter coexist on the same display, switchable between modes through five buttons positioned below the screen. Not mechanical buttons that fail. Not membrane switches that degrade. Proper tactile buttons with satisfying action, positioned for blind operation, sized for confident fingertips.

The modes programmed:

- Analog needles: VU meters rendered as swinging pointers, physics simulated so perfectly you forget you’re watching pixels

- Original replica: Modern recreation of Pioneer’s original meter aesthetic, nostalgia without the limitations

- 1/3 Octave spectrum analyzer: Frequency response displayed in real-time, revealing what tape captures across the audible spectrum, showing what the original RT-909 could never visualize

Counter, mode selection, color control: all accessible through those five buttons. The interface responds instantly — 600MHz processing means zero lag between thought and action.

Silver Constellation

Metal letterforms — silver-toned alloy creating brilliant contrast against Caveman Black void. These characters share the same integration process as our bronze work: proprietary bonding making letters inseparable from panels. But silver against black creates different aesthetic entirely — sharper, colder, more technological. Where bronze speaks of antiquity, silver speaks of precision. Of laboratories. Of instruments that measure rather than merely function.

The RT-909’s geometric modernism demands this contrast. Bronze would soften. Silver sharpens.

Original Knobs: Redemption Through Polish

Pioneer’s original control knobs possessed good design, good feel, good mass. We retained them. Not out of nostalgia — out of recognition that they didn’t require replacement, only renewal.

Each knob removed, cleaned completely, then polished to original luster. Surfaces that had dulled through decades of handling restored to showroom perfection. Sometimes what exists needs only attention, not reinvention.

These knobs now operate controls they never knew — digital systems responding to analog input, vintage tactility directing modern processing.

New Legs, New Stance

Even the legs — structural elements most would ignore — replaced entirely. Not because originals failed structurally. Because aesthetics extend to the foundation. Because every visible element contributes to presence.

New legs machined to complement Black Stone’s geometric severity. The machine sits differently now. Stands with more authority. Small detail. Significant impact.

Magnetic Heads: Audio Purity

New heads installed — the interface between magnetic domains on tape and electrical signals in circuits. This is where fidelity lives or dies. Original heads, regardless of condition, carry decades of wear. Replacement with new-old-stock ensures the RT-909 captures and reproduces with precision Pioneer intended when the machine was born.

Immediacy

Offered for acquisition. Sold rapidly. Collectors recognized the transformation: forty-year-old industrial design meeting processing power from this decade, vintage aesthetic housing contemporary capability. The RT-909 that refuses to age, now genuinely ageless.

Singularity

No other RT-909 contains this exact combination: 600MHz processing, five-inch display, spectrum analysis, 316L stainless pinch rollers with miniature bearings, silver letterforms against obsidian void. This specific intersection of vintage geometry and modern electronics exists once.

Black Stone stands alone. Complete. Already legend.

Status: Sold

Completion: Early 2024

Time Investment: 9 months

Current Location: Private collection

Documentation: Workshop photography available upon request

Note: This RT-909 transformation represents unique approach. Future RT-909 projects will explore different directions.

For those seeking similar transformations or to commission your own instrument, contact us directly or through our authorized dealer network. Each creation is unique; timelines begin at 6 months for less complex transformations, 12+ months for comprehensive reimaginings.

PIONEER RT909 Midnight Blue

Pioneer RT-909 — Midnight Blue Edition

6 months of technological resurrection

Prussian Depths

Before Black Stone came Midnight Blue — our first RT-909 transformation, exploring the model’s timeless geometry through color rather than void. This was discovery. This was learning what the RT-909 could become when forty-year-old industrial design met contemporary capability.

Midnight Blue from Prismatic Powders: not navy, not royal blue, but something deeper. Prussian blue’s mysterious depths, the color of night sky between stars, of deep ocean where light surrenders to pressure and darkness. The kind of blue that shifts with viewing angle, that appears nearly black until light finds it, then blooms into richness.

This blue speaks differently than black’s absolute void. Where obsidian absorbs, midnight blue holds light briefly before releasing it transformed. The RT-909’s angular geometry — prescient design from 1985 that predicted minimalism decades early — gains warmth through this color choice. Technology softened without losing authority.

The Genesis Approach

Against Midnight Blue’s depths, laser-engraved letterforms create subtle dimensionality. This predated our metal inlay development — we had not yet perfected bronze integration, had not yet discovered how metal could become inseparable from panel. Here, precision lasers burn through powder coat to reveal aluminum beneath, creating graphics through controlled ablation rather than applied material.

The effect: understated elegance, text that whispers rather than shouts. Letterforms emerge from blue depths like phosphorescence in dark water, visible yet integrated, present without demanding attention. This taught us restraint before we learned extravagance. Both have place. Both serve purpose.

The Transformation

Complete disassembly to constituent parts — bolts separated from panels, circuits divorced from chassis, the RT-909 reduced to archaeological scatter. Every fastener replaced with stainless hex-head permanence. Every capacitor extracted, discarded, replaced with audiophile-grade components. Every belt renewed. Every bearing replaced. Lubrication points addressed methodically.

Original electronics — primitive implementations from when 8-bit processing seemed advanced — removed entirely. Circuit boards containing 1980s logic: discarded without sentiment. In their place: custom PCBs housing 600MHz processing power that would have seemed impossible when Pioneer designed the original. Audio ADC sampling with resolution the original engineers never imagined. High-resolution screen drivers creating digital smoothness that mimics analog grace.

The five-inch display: singular screen replacing twin primitive meters, offering multiple VU modes. Analog needles that swing with physics-perfect simulation. Original-style recreation for those who love vintage aesthetics. Real-time 1/3 octave spectrum analysis revealing what tape captures across audible frequencies. Five buttons positioned below for intuitive control — counter, mode selection, color adjustment. Tape counter precision to 1/100 second via high-precision encoders, because editing demands certainty.

Pinch rollers completely redesigned: 316L stainless steel machined with miniature precision bearings inside, non-magnetic properties critical near tape heads, surfaces polished to mirror finish. Original knobs retained and repolished — recognition that good design endures, needs only renewal rather than replacement. New magnetic heads. New legs altering the machine’s stance, its relationship with surface beneath.

The RT-909’s forty-year-old industrial design elevated through contemporary electronics, proving that timeless geometry needs only proper execution to remain perpetually relevant.

She Who Recognized

Offered for acquisition. Claimed rapidly by a woman who understands: equipment need not be masculine to be serious, blue need not be soft to be powerful, beauty and performance exist without contradiction. A lady audiophile whose ears hear what specifications only suggest, whose eyes recognize that midnight blue against polished aluminum creates elegance unavailable to black alone.

This RT-909 found its match — someone who appreciates both the technological resurrection and the aesthetic consideration, who values the spectrum analyzer as much as the color choice, who understands that obsession serves art regardless of who creates or who acquires.

First Steps

Our first RT-909 transformation. What we learned here informed Black Stone, which followed two years later. Midnight Blue taught us the platform’s potential, revealed how far forty-year-old geometry could stretch into contemporary capability. We discovered that the RT-909’s design language — angular, geometric, uncompromising — accepts modern electronics naturally, as if Pioneer’s designers anticipated this evolution.

This edition preceded our metal letterform development, representing a specific moment in our workshop’s evolution. Not primitive. Not incomplete. Simply different — exploring aesthetic territory through subtraction and precision rather than applied materials and dimensional contrast.

Status: Sold

Completion: 2022

Time Investment: 6 months

Current Owner: Private collection, lady audiophile

Note: Our first RT-909 transformation. Black Stone followed in 2024, exploring the same technological transformation through different aesthetic philosophy.

Each RT-909 transformation explores unique territory. No repetitions. Only evolution. This was the beginning.

Studer A807 Reel To Reel Haven Edition

Studer A-807 — Reel To Reel Haven Edition

Collaboration between craftsmen, gift between friends

Beyond Commerce

This machine exists outside our typical narrative. No client commissioned it. No collector acquired it. No money exchanged hands. This A-807 represents something rarer: collaboration between craftsmen who respect each other’s work, gift between friends who understand that some creations serve community rather than commerce.

Ryan O’Connor — founder of Reel To Reel Haven, keeper of analog knowledge, advocate for tape’s continued relevance — needed a studio workhorse. We provided the skin. He provides the soul.

Division of Labor

Honesty: we did not rebuild this machine’s internals. Another technician handled repair and recalibration, ensuring the A-807’s legendary Studer reliability functioned as intended. Our contribution: appearance only. Surface, not mechanism. Aesthetic, not electronic.

This is not diminishment. This is specialization. We do what we do best — transform surfaces into statements — while others handle what they do best. The result serves the machine better than singular obsession could.

Foundation Reimagined: The Cart

The original cart with wheels — functional but aesthetically compromised, utilitarian design from era when appearance mattered less than mobility — discarded entirely. In its place: completely new wheeled cart embodying contemporary geometry.

Black textured powder coat provides durable foundation, surface that hides marks rather than revealing them, appropriate for studio equipment that faces daily use and inevitable abuse. On the flanges: Alter Ego Appearance logos, subtle signature indicating who dressed this machine.

The cart elevates the A-807 literally and figuratively — better proportions, cleaner lines, presence that announces this is not generic studio equipment but considered tool, elevated through attention.

Distressed Oak: Designed to Age Gracefully

Side panels machined from white oak, then deliberately distressed and darkened before installation. Not pristine. Not perfect. Deliberately aged, intentionally imperfect, pre-weathered so that future wear becomes continuation rather than degradation.

This is strategic. Studio equipment suffers. Tape machines in professional environments endure what home listening equipment never experiences — constant handling, gear changes, tape threading, accidental impacts, the accumulated violence of daily use. Most finishes deteriorate under this treatment. These panels improve.

Like quality denim, these oak panels gain character through wear. Scratches become patina. Dings become personality. The distressing we applied provides template — future damage follows established aesthetic rather than contradicting it. The panels will look better in five years than today. Better still in ten.

This is wabi-sabi applied to professional audio: embracing imperfection, celebrating wear, designing for time rather than fighting it.

Identity: Reel To Reel Haven

Panels powder coated, then adorned with metal Reel To Reel Haven logo — not stickers, not vinyl, but dimensional metal letters integrated into surface. Some letters cast from aluminum bronze (replacing Studer’s original red lettering), catching light with warm metallic glow. Other letters receive white powder coat, creating contrast without chaos.

The logo announces this machine’s home, its purpose, its context. This A-807 belongs to Reel To Reel Haven studio, serves Ryan’s work preserving and advancing tape culture, exists as tool for those who still believe analog offers what digital cannot replicate.

Studio Life

This machine will not rest in climate-controlled listening room, will not receive white-glove treatment, will not live behind glass as museum piece. It works daily at Reel To Reel Haven, serving whoever needs professional-grade tape handling, available to those Ryan mentors and supports.

The distressed oak will gain new distress. The powder coat will accumulate scratches. The bronze letters will develop patina from hundreds of hands. This is correct. This is intended. We designed this appearance specifically for the abuse it will receive, ensuring that wear creates beauty rather than destroying it.

Friendship Over Commerce

No invoice. No payment. No transaction. Just two craftsmen — one preserving tape culture through education and community, one transforming machines through obsessive attention to surface — recognizing alignment of purpose.

This A-807’s appearance upgrade represents investment in community rather than profit. Ryan’s work at Reel To Reel Haven advances analog’s relevance. Supporting that work serves everyone who believes tape still matters. Some collaborations transcend commerce.

Singularity Through Purpose

This remains the only Studer A-807 wearing Alter Ego Appearance aesthetic, the only one built specifically for Reel To Reel Haven, the only one created as gift rather than commission. It exists in specific place, serving specific purpose, representing specific friendship between craftsmen.

You cannot commission this. Cannot purchase this. Cannot replicate this, because replication would miss the point entirely. This machine’s value lies not in materials or technique but in context — what it represents, who it serves, why it exists.

It lives at Reel To Reel Haven. Working. Aging. Becoming more itself through use.

Status: Never for sale — Exclusive creation for Reel To Reel Haven

Completion: 2022

Current Location: Reel To Reel Haven studio, in active service

Note: Gift collaboration between Alter Ego Appearance and Ryan O’Connor. This A-807 serves the tape community through Ryan’s educational work and studio access.

Not all creations pursue profit. Some serve community. This is one of those.

Prima Opera: The First Works

The Genesis Trilogy — Early Works

Technics RS-1700 Contrā Colōrēs • RS-1500 Black and White • RS-1506 Montego Blue

Origins During Isolation

COVID-19 locked the world indoors. While others baked bread or learned languages, we transformed tape machines. These three instruments — RS-1700, RS-1500, RS-1506 — represent Alter Ego Appearance’s genesis, the beginning of evolution from concept to obsession.

Created during pandemic isolation, these machines taught us foundational lessons: how powder coat flows, how wood accepts finish, how bolts and capacitors matter even when electronics remain original. We had not yet developed metal inlay techniques. Had not yet cast bronze knobs. Had not yet perfected the processes that would define later work.

These are first steps. Honest. Unrefined compared to what followed. Essential.

Shared Philosophy: Simplicity as Foundation

All three machines share core approach: surface transformation while respecting original electronics. Technics’ engineering from this era needs no improvement — these machines sound as their designers intended. We addressed what time degrades: worn finishes, aging capacitors, corroded fasteners.

Every bolt replaced with stainless hex-head permanence. Every capacitor extracted and renewed with modern audiophile-grade components. Mechanical foundations rebuilt while electronic character preserved.

Side panels: wenge wood, dark and dense, finished simply without protective flanges. Wenge possesses natural oils that resist moisture, grain patterns that create visual depth, darkness that complements powder-coated panels. No stabilization required. No elaborate treatment. Just selection, finishing, installation.

Technics RS-1700 — Contrā Colōrēs Edition

“Against Colors” — Monochrome Philosophy

The most evolved of this trilogy, exploring contrast through texture rather than hue. Panels powder coated in monochromatic scheme, but here we achieved dimensional typography: stainless steel letterforms creating tactile contrast against matte surfaces.

Contrā Colōrēs — Latin for “against colors” — captures the philosophy: refusing chromatic distraction, creating visual interest through surface variation alone. Brushed stainless steel lettering catches light differently than surrounding powder coat, creating subtle drama without color’s obvious tools.

This machine taught us that metal letterforms could work, should work, must work. Everything that followed builds on lessons learned here.

Completion: 2020

Status: Sold

Technics RS-1500 — Black and White Edition

Dichotomy as Design

Black Cast powder coat from Prismatic Powders: absolute darkness, void-like depth. Against this, white powder-coated letterforms create stark binary contrast. No gradation. No subtlety. Just black and white, absence and presence, zero and one.

This RS-1500 explores digital philosophy through analog equipment: binary opposition, clear delineation, refusal of middle ground. The aesthetic predicts our later work with Caveman Black against white bronze, though here we achieve contrast through powder coat alone rather than dimensional metal.

Wenge panels provide only concession to warmth — organic texture against geometric severity.

Completion: 2021

Status: Sold

Technics RS-1506 — Montego Blue Edition

Caribbean Depths

Montego Blue from Prismatic Powders: aquamarine depths, ocean color between shallow turquoise and deep navy. The name evokes Caribbean waters, tropical clarity, warmth despite depth.

This color choice — our most adventurous during this period — explores what tape machines could look like beyond traditional blacks and silvers. Montego Blue brings unexpected warmth to Technics’ angular geometry, softening industrial severity without diminishing authority.

Powder-coated white letterforms provide necessary contrast against blue depths. Wenge panels ground the composition, preventing the blue from becoming too playful, too light, too tropical. The combination: serious equipment wearing unusual color confidently.

Completion: 2020

Status: Sold

Learning Through Making

These three machines represent Alter Ego Appearance learning to walk before running. We had not yet perfected bronze casting. Had not yet developed proprietary metal inlay processes. Had not yet integrated LCD screens or machined custom control surfaces.

But we understood: surfaces matter. Colors affect perception. Wood complements metal. Fasteners and capacitors, though invisible during operation, contribute to longevity and reliability. Attention to detail separates restoration from transformation.

Every technique we employ now — bronze letterforms, fossilized wood panels, CNC-machined controls, custom electronics — evolved from lessons learned during COVID isolation while creating these three instruments.

They are not primitive. They are foundational. They represent moment when concept became practice, when possibility became reality, when Alter Ego Appearance transformed from idea into workshop producing actual machines.

Pandemic Legacy

COVID-19 gave us time. Isolation provided focus. Unable to source exotic materials during supply chain chaos, we worked with what we could obtain: powder coats from Prismatic Powders, wenge wood from limited suppliers, capacitors from audiophile vendors still shipping.

Constraints breed creativity. These three machines exist because pandemic forced us to perfect simple approaches before attempting complex ones. We learned powder coat application when we couldn’t source bronze. We mastered wood finishing when CNC machining seemed impossible. We rebuilt electronics when custom circuit boards were unavailable.

By the time supply chains recovered, we had mastered fundamentals. Everything after builds on this foundation laid during lockdown.

The Genesis Trilogy

Completion: 2020-2021 (COVID-19 era)

Status: All three sold

Significance: First machines establishing Alter Ego Appearance methodology

Note: These represent our origin story — simpler than current work, essential to everything that followed.

Every evolution requires genesis. These three machines are ours.